The success of a company is related to its ability to offer innovative, high-performance solutions that can stand out on the market. DIECI, which in 1983 was the first European company to develop and manufacture a range of telescopic handlers, has always believed in the importance of looking to the future, by offering cutting-edge products. This distinctive trait has enabled us to produce over 140 models, which are designed internally by our R&D (Research & Development) department.

We talked about the importance of research and development activities with Enrico Ognibene, DIECI technical manager, who has been head of the R&D department since 2011.

What does your work consist of?

My job as technical manager mainly involves coordinating the development and evolution of all DIECI products. In the R&D department we have a team of 25 people divided between the office and the prototype and testing section. We are responsible for supervising and managing everything design-related, from the concept to certification and type approval for the various target markets.

Our offering is extensive and structured, we always have ongoing projects to monitor or pursue.

As technical manager, I deal with various activities including:

- drawing up guidelines for the development and implementation of new technologies;

- monitoring various research projects;

- carrying out, together with specialists, the project verification and approval phase;

- evaluating and implementing strategic choices, in coordination with the commercial/marketing area, to carry out specific initiatives together;

- monitoring the health of products, in terms of both production and coordination in the field;

- discussing and checking, in conjunction with other departments such as Production, Quality, Purchasing and After-Sales, the actions to be taken to improve the products, comfort and safety.

What is the R&D department’s role within Dieci?

My department designs and tests all new vehicles as well as new components. We take care of everything related to conception, design, planning and testing. All these processes relating to DIECI vehicles are carried out internally or in a co-design process with suppliers.

Also essential to this process is validation of the vehicles, which must be compliant with existing regulations and our standards.

How has telehandler (or other vehicle) technology evolved to date, and what have been the drivers of this sector’s development?

The most influential aspects that have driven the evolution of our vehicles in the last 20 years are mainly linked to safety, environmental impact in terms of emissions from diesel engines, and operator comfort. The development processes were further boosted by competition with other players in the market, which spurred us into researching new technical solutions and improving the design of both our telehandlers and self-loading concrete mixers.

An equally important aspect that has guided the development of the sector was the introduction of the electronic control component. Today we have achieved fully integrated management of the vehicle and transmissions through electronic controls that communicate with each other, also interfacing directly with the systems that manage vehicle safety.

You have held the position of Technical Manager for over 10 years. What are your proudest achievements in that time?

I am proud of all the work I’ve done with my colleagues these past 10 years. If we compare the photos and data sheets of the models we produced 11 years ago with those of today, the change and the great work done is self-evident.

There are some innovative projects that were only possible thanks to the trust of the owners. They were pioneering projects for this sector, which become market benchmarks that even made the competition sit up and take notice.

To name a few of the most important ones in recent times:

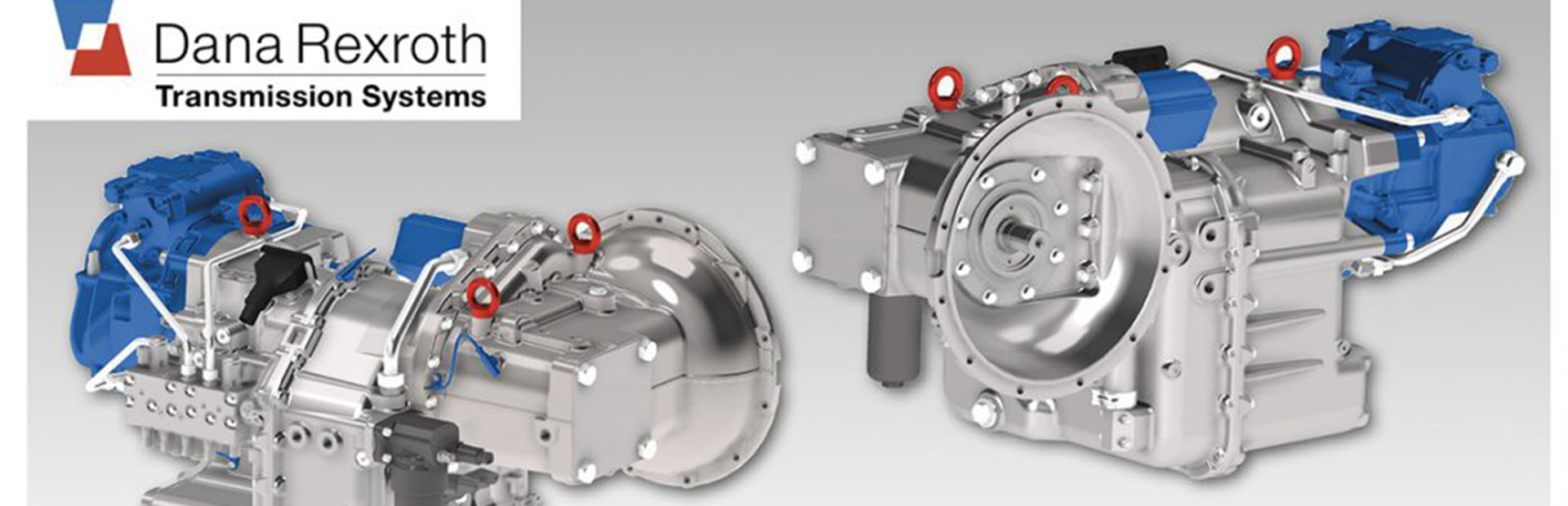

- Vario System transmission, developed with Dana and Rexroth, two global players in the hydraulics and transmission sector It was a project that we were the first to carry out and that has now become widely adopted on many agricultural and construction vehicles, including in sectors complementary to ours.

- Powersplit HVT1, the first HVT1 transmission implemented on a telehandler. We previewed this project at Agritechnica 2019 and we are preparing to put it into production at the end of this year.

- The Giugiaro cabin, designed together with ItalDesign, promotes the comfort and safety of operators working in DIECI telehandlers.

Together with Walvoil you recently won the EIMA Technical Innovation Competition thanks to the innovative ALS ADAPTIVE LOAD SENSING project. Can you tell us about it?

Walvoil is a historic brand in Emilia-Romagna’s hydraulic industry and one of the world’s leading manufacturers of hydraulic, electronic and mechatronic products.

Hydraulic systems are an essential part of agricultural vehicles, especially telehandlers. In these systems, to ensure simultaneous control of movements, the hydraulic pump generates a higher pressure than is really needed, a set value called the stand-by margin, which constitutes a considerable loss of energy that limits the vehicle’s overall performance and increases wear and fuel consumption, thereby reducing efficiency and impacting the environment.

Adaptive Load Sensing, designed by Walvoil, is capable of modulating the stand-by margin value depending on the vehicle’s actual work needs, automatically changing it only when and by the exact amount required.

Thanks to the ALS – Adaptive Load Sensing project, the energy requirement is reduced by 5-6%, leading to considerable fuel savings. This is a major advantage especially for those vehicles, such as in the agricultural sector, that are used continuously for many hours. If we assume that a car consumes 10 litres of diesel in one hour, this system reduces that consumption to 9.5. That’s a difference of 0.5 litres/hour which, if applied on a weekly, monthly or annual basis, leads to considerable savings.

The partnership stemmed from their need to find a partner that could test the component on a vehicle, so as to verify its effectiveness. We delightedly agreed to work with them, creating a vehicle that incorporates the components they developed, before testing it and jointly creating the integrated management software.

During the system integration and development phases on the Dieci vehicle, we developed specific control logics for the telehandlers and the sharing of ideas and experiences further informed and refined the initial concepts of ALS.

What are you currently working on (if you are permitted to say) and what challenges do you envisage for the future?

Right now we are working on putting into production the Agri Max Power X2, which is the top-performing vehicle in the Dieci agricultural range. This is an ambitious goal that will introduce a telehandler with Powersplit transmission (HVT-1) onto the market for the first time.

Another important project, but one which we cannot preview, is the updating of the Pegasus rotary telehandler range, which we will present at Bauma in late October 2022.

Finally, our other new developments include the new IDEA display, co-designed with MTA. This instrument is already present on the AgriMax and AgriPlus models. Being so easy to use, MTA Studio has allowed Dieci to develop the application software totally in-house, maximising its customisation potential.

Looking ahead, certainly one area of research is to identify solutions for reducing CO2 emissions, including electric power. The latter is a complex sector, however. Already in the automotive sector there are delays, mainly due to the difficulty of creating adequate infrastructures for charging electric vehicles. In trade journals there is talk of legal constraints being postponed from 2030 to 2035 at European level. As regards the telehandler sector, several compact vehicle prototypes have been made. Currently, however, development and production costs related to vehicle performance are not in line with traditional combustion engine vehicles. There is a great deal of research going on, but several aspects are delaying the electrification process, not least the difficulty in sourcing materials.

Bear in mind that to develop a new vehicle takes at least two years, which is a very long time for the market and for the technological evolution that is now underway in the electrical components sector. There is a risk of designing models that are already obsolete by the time of the production launch. Full electric is certainly one of the challenges for the future, but it is a path that is not well defined, especially in terms of costs, performance and results.

Do you want to add anything?

I am very happy with the growth process that our company has undertaken by pursuing numerous innovative projects. I believe that today we can further differentiate ourselves by shifting our gaze even more from our competitors to our customers, continuing to focus on their requests, needs and the requirements that they have in the field.

Our identity is strong and I think that this change of perspective may be the most interesting catalyst that enables DIECI to take another step forward in terms of production and innovation.