Haymaking is the process of collecting and drying fodder. Huge demand among farms for hay has pushed suppliers to find suitable solutions to guarantee its quality while safeguarding the cost-effectiveness of the process. One winning response is the use of telehandlers, a multi-functional agricultural vehicle that lends itself to multiple stages of the haymaking process.

What haymaking techniques are there?

Haymaking involves four stages: cutting, drying, raking and pressing. There are two main haymaking techniques that differ in terms of how the fodder is dried:

- In traditional haymaking, the whole process takes place in the field.

- In two-step haymaking, after first being dried in the field, the hay is then brought inside the barn to complete its cycle. With this technique, the forage can be dried in the barn either loose or already packed into bales.

The drying stage is essential to protect the quality of the product. It is important to take into account that:

- In traditional haymaking, drying causes a 10-13% loss of dry matter, compared with a 4-10% loss in two-step haymaking.

- With both techniques there is also a loss of nutrients, which amounts to 10-15% with the traditional technique compared with just 3-10% in two-step haymaking.

Handling large quantities of forage requires great care and every business must strike the right balance between investing in machinery and human resources. Whatever technique is chosen, the forage must be lifted, collected and transported in large quantities. In this last stage (handling), telehandlers have proven to be extremely effective.

How hay is cut and conditioned

At the cutting stage, it is important to maintain an even cut that is at least 7cm above the ground. Carrying out careful and meticulous mowing preserves the forage and the quality of the field. Good cutting means that:

- the hay is not contaminated by the earth

- soil is not eroded, thereby avoiding long-term damage

- a level cut is achieved

Cutting is followed by conditioning, which speeds up drying and makes the moisture content more homogeneous. Nowadays it is possible to buy mowers with a working width of up to 4 metres, which help to save time and protect the quality of the product.

Raking and collecting hay: from windrows to bales

The haymaking cycle is completed by raking and collecting, which involves compressing the dried fodder into bales. Raking first accumulates the hay into long piles called windrows, which simplifies the collection stage.

The forage is then pressed into bales, which can have different shapes and density (kg/m³), factors that influence its quality, especially as regards the dispersal of internal moisture. The ideal density is below 140 kg/m³, to facilitate water loss.

This completes the haymaking process. The baled product can be stored inside barns, fed to livestock or sold.

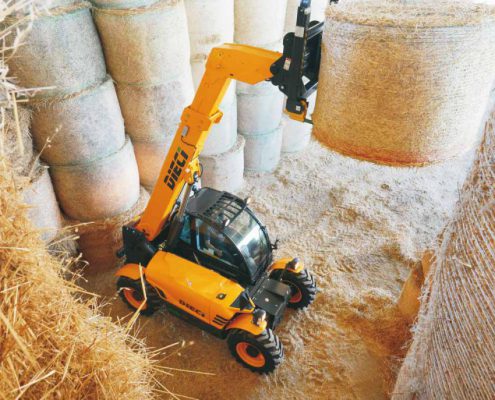

Telehandlers help to transport hay bales (both cylindrical and rectangular) and are popular with many farmers due to their flexibility and speed in moving and stacking bales. A telehandler accelerates this stage of the process, both in the field and on the farm.

The main advantages of using a telehandler are:

- The telescopic boom provides reach and flexibility of movement. A telehandler can reach higher and further than a tractor or forklift truck: for example, it can stack cylindrical bales up to six high and several rows deep.

- The multi-purpose equipment ensures a customisable vehicle with an extended range of uses: on a farm, telehandlers are an all-round workhorse that can be used to fill, transport, lift, stack, hitch, fork, tow and much more.

The benefits of DIECI telehandlers for haymaking

If a farm were to use a different vehicle for each activity, the effectiveness and costs of the workflow would be severely impacted. Agricultural telehandlers are a tried-and-tested solution to this need. Their strength is their versatility: they can be used on farms for multiple activities such as haymaking, saving both money and time.

DIECI vehicles stand out on the market for their reliability, strength and versatility, making them ideal for the needs of small and large businesses alike, with solutions that are adaptable to the most arduous work conditions.

In addition, the DIECI line-up is complemented by specialised accessories and equipment that further increase the functionality of our agricultural telehandlers. Specifically, our vehicles can be equipped with bale clamps, bale spikes, power take-off, forks, lifting hooks and much more.

The DIECI range offers a solution to any need, with each vehicle offering different maximum reach lengths, load capacities, dimensions, power output and speed. We have the ideal vehicle for every farm, taking into account specific needs such as handling, space and type of job, plus cutting-edge safety systems and unrivalled comfort.

A range of agricultural telehandlers for any requirement:

- Mini Agri: versatile and easy to handle, this is the ideal solution for small-scale tasks

- Agri Farmer: comfortable and safe, with an excellent load capacity to meet every lifting need

- Agri Plus: top-of-the-range technology, innovation and comfort

- Agri Max: solid and powerful, with incredible load capacity

- Agri Star: versatile and fast, perfect for handling loads in confined spaces, ideal for towing on the road and unloading/loading products

- Agri Pivot: the perfect answer for working in confined spaces